For industries where conditions are tough, having durable identification solutions cannot be overstated. Whether in industrial, construction, or automotive, keeping labels clear to read and reliable in harsh conditions is crucial for safety, efficiency, and compliance.

In these circumstances, metal nameplates stand out as a robust solution, engineered to endure extreme conditions while preserving critical information.

Reliable identification depends not just on clarity but also on withstanding harsh environments. Metal nameplates excel at this, as they can handle various tough conditions.

Here’s how they stand out:

Fight corrosion

In hot, moist, or saltwater environments, materials can easily get damaged. Metal nameplates resist corrosion, unlike other materials, which can get ruined by moisture, chemicals and other corrosive agents commonly found in industrial settings.

Handle extreme temperatures

Metal nameplates can take on very high and very low temperatures without getting damaged or losing their integrity. This means they stay readable and intact in all sorts of weather, thanks to their special finishes.

Resist sun and weather

Aluminium nameplates maintain their clarity and durability even after prolonged exposure to sunlight and harsh weather conditions, thanks to UV sunlight and temperature-resistant finishes.

Withstand impact

Due to their sturdy construction, metal nameplates are tough and don’t get easily damaged by physical impacts or abrasion. This makes them ideal for rough industrial environments.

Long-lasting

Metal nameplates maintain their quality and appearance for years, reducing the need for frequent replacements, which saves both time and money.

Fade resistant

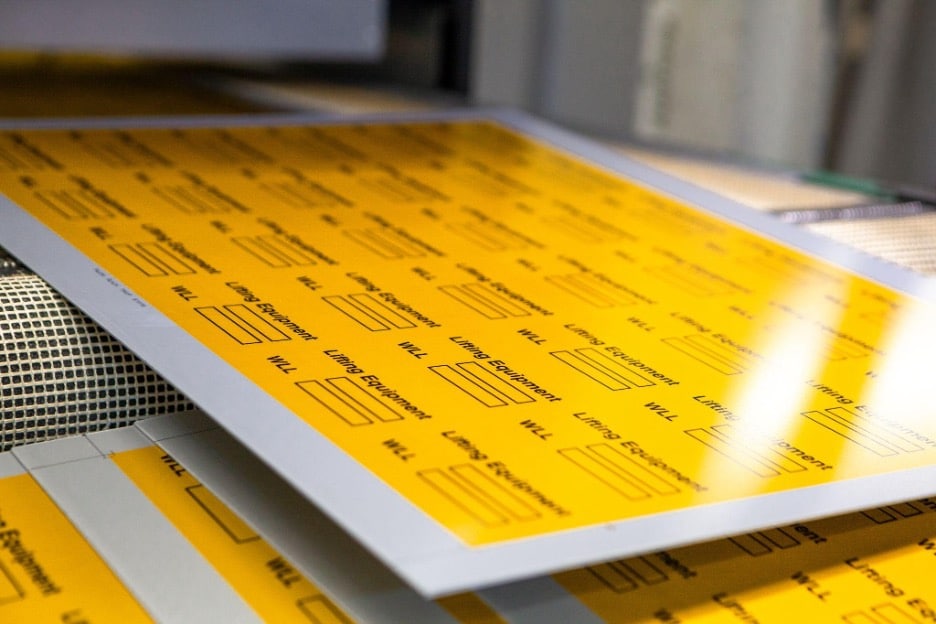

The colour of aluminium is very stable, so it will not fade or discolour over time. This makes aluminium a great choice for nameplates that need to be highly visible, such as those on machinery or industrial equipment.

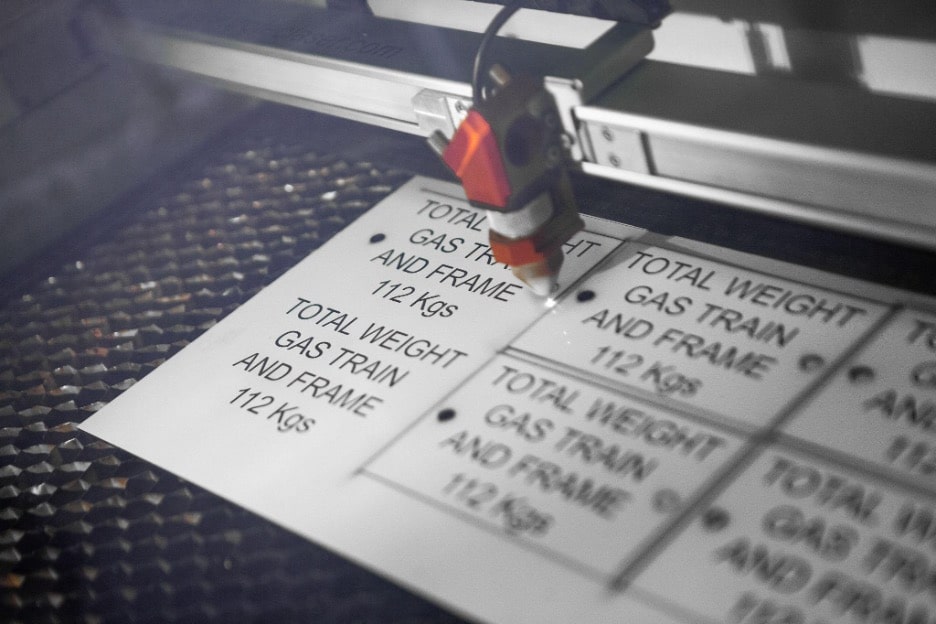

At MTM, we use open-pore anodised aluminium, where the print is sealed within the aluminium for businesses that require a durable and long-lasting nameplate.

Metal nameplates have a wide range of versatile applications across various industries.

In manufacturing facilities, metal nameplates are indispensable for equipment identification and safety labelling. Their durability ensures that vital information remains intact, enhancing operational efficiency and safety compliance.

Recently, we assisted a global power management company that required nameplates for oil rigs, which needed to withstand harsh weather conditions and saltwater exposure, all while meeting UL Marking requirements.

Given that the nameplates would be exposed to such a harsh environment, we carefully considered the materials before we opted for subsurface-printed aluminium. This choice guaranteed that the nameplates would be less likely to fade or scratch and would be more durable overall.

Across automotive and transportation sectors, metal nameplates are widely utilised for vehicle identification, branding, and safety labelling. Previously, we helped a globally recognised automotive brand with replicating old plates from several classic cars that no longer existed and needed to look authentic.

We worked collaboratively with the company, discussing exactly what was needed, from shape and style to adhesion, before visiting their site to see the vehicle and take measurements.

To read how we’ve helped other companies and industries, visit our case studies.

At MTM Products, we’re constantly pushing to deliver the right solution for you using trusted, tried and tested processes.

We take the time to customise our metal nameplate solution to your industry and needs.

We understand that many of our customers operate in highly regulated environments, creating a solution that’s tailored to suit.

For example, in the rail industry, we utilise “open-pore” anodised aluminium, where the print is sealed within the aluminium to create a solution that’s resistant to fading.

MTM Products are a UL Solutions Authorized Label Supplier, and are able to advise on material combinations that comply with UL969 standards and have a first-class facility designed especially for the manufacture of high-quality metal nameplates.

Whether you’re dealing with extreme temperatures, corrosive environments, or the wear and tear of industrial use, our nameplates ensure your critical information remains intact and legible.

As a Made in Britain member, we’re committed to ensuring that our customers receive labels and signage that is of the highest quality.

Speak to our friendly team to discover how our durable and expertly crafted metal nameplates can enhance your operations and ensure compliance in any environment.